#8 Mirror Finish

#8 Mirror Finish

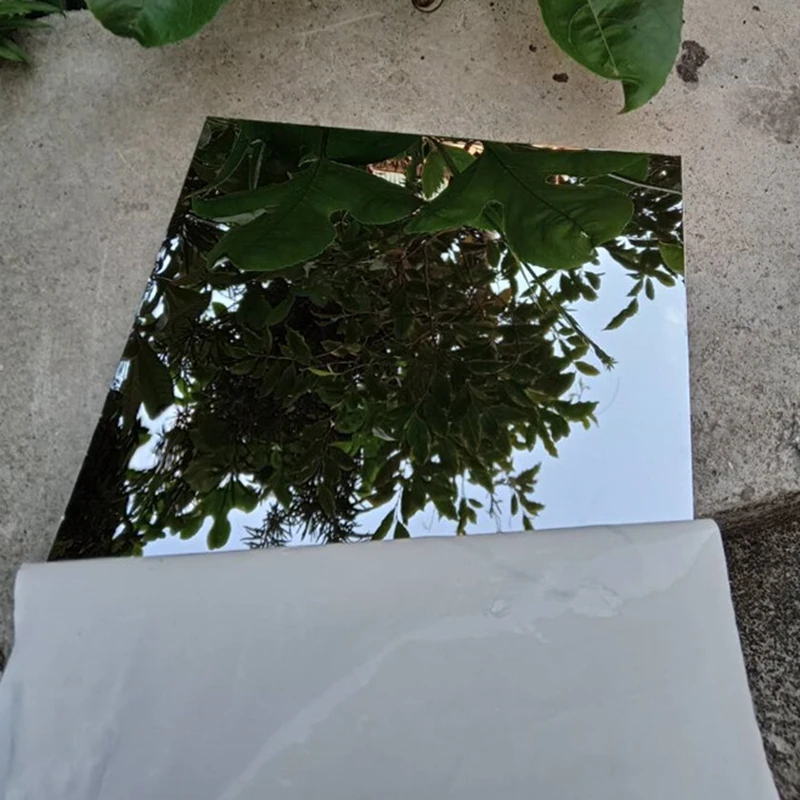

What is #8 Mirror Finish?

#8 mirror finish, also known as a mirror polish, is a highly reflective surface finish on stainless steel. It is achieved by polishing the metal with progressively finer abrasives until a smooth, reflective surface is achieved. The finish is so reflective that it resembles a mirror, hence the name. The result is a finish that has a specular reflection, which means it reflects light in a way that creates a clear image.

How is #8 mirror finish achieved?

#8 mirror finish is achieved through a series of polishing and buffing processes. The polishing process involves the use of abrasive materials, such as sandpaper, to remove any imperfections and scratches from the surface of the material. The buffing process involves the use of buffing compounds, such as rouge, to achieve a smooth and reflective surface.

The quality of the #8 mirror finish is determined by the level of reflectivity achieved. The reflectivity is typically measured using a gloss meter, which measures the amount of light reflected from the surface of the material. The highest quality #8 mirror finish can achieve a reflectivity of up to 98%.

Applications of #8 Mirror Finish

#8 mirror finish is used in a wide range of applications where a highly reflective surface is desired. Its reflective properties make it ideal for applications that require high optical clarity and a clean, polished look. Some common applications of #8 mirror finish include:

- Architectural features: The reflective properties of #8 mirror finish make it a popular choice for architectural applications, such as elevator doors, escalator cladding, and decorative paneling.

- Automotive industry: #8 mirror finish is often used in the automotive industry for decorative trim, exhaust tips, and grilles.

- Food and beverage industry: Stainless steel equipment used in the food and beverage industry, such as mixers, tanks, and piping, are often finished with #8 mirror finish for their hygienic properties and easy cleaning.

- Medical industry: The high optical clarity and smoothness of #8 mirror finish make it a popular choice for medical equipment, such as surgical tools and dental instruments.

Frequently asked questions

Q: Is #8 mirror finish the same as a chrome finish?

A: No, #8 mirror finish is achieved through mechanical polishing and buffing, while a chrome finish is achieved through a plating process.

Q: How do I maintain the #8 mirror finish?

A: To maintain the mirror finish, clean the surface regularly with a mild soap and water solution or a specialized stainless steel cleaner. Avoid using abrasive cleaners or scrubbers that can scratch the surface.

We provide #8 mirror finish for all metal types. Get in touch with our ASMG team to discuss your project and request a quote.

Request a Quote

Take the First Step in Your Project with Our Quick and Convenient Quote Request Form.