Products

Pipes & Tubes

We provide seamless and welded pipes in lengths and cut pieces, with NPS ranging from 1/4″ to 12″ and wall thicknesses from schedule 10 to XXH, all resistant to corrosion. We also offer custom non-standard pipes with various O.D. and wall thicknesses, and provide additional processing services like drilling, boring, milling, and threading.

Our alloy tubing options include welded and seamless forms with OD from 1/16″ to 2″ and wall thickness up to 0.083″. Available in different alloys and sizes, including heat exchanger tubes, condenser tubes, and instrumentation tubes in standard lengths, custom lengths, and u-bends.

Available Alloys

Sheets & Plates

We offer a wide range of corrosion-resistant alloy sheets from 0.025″ to 0.157″ thick, with options for full sheets and standard shapes like squares, rectangles, circles, rings and strips, or custom shapes as needed. We also carry an extensive inventory of 3/16″ to 3″ thick alloy plate and offer plate processing services like shearing, plasma cutting, waterjet cutting, and laser cutting for standard or custom shapes

Available Alloys

|

|

Fittings & Flanges

We stock corrosion-resistant alloy fittings, including buttweld from schedule 10 to 80, 150# threaded, 3000# socket weld and threaded fittings, with standard and custom elbows, tees, caps, unions, reducers, crosses, laterals, stub ends, return ends, nipples, plugs, pressure fittings, ferrules, and connectors in various schedules and sizes. Our flange options include Blind, Slip On, Socket Weld, Threaded, Weld Neck, Lap Joint, Tongue and Groove, Ring Type Joint, and Orifice flanges, in corrosion-resistant alloys. We offer both standard and custom flanges to meet your needs.

Available Alloys

|

|

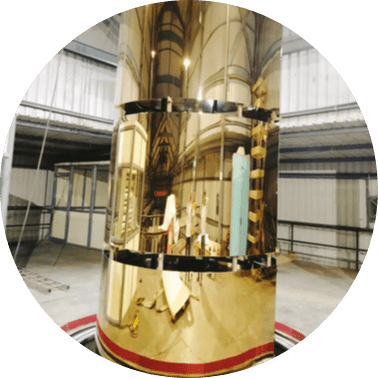

Polished Steel Products

We offer polishes on 50″ wide stainless steel coils for appliance, architectural, and truck trailer markets. Finishes available include #3, #4, or custom options in thicknesses ranging from 0.012” (30 Ga.) to 0.120” (12 Ga.), both wet and dry.

Polishing stainless steel improves the surface finish and enhances its sanitary properties. The process involves smoothing the surface with abrasives to achieve a high-quality finish. The methods and effects of polishing vary depending on the specific stainless steel product.

Available Alloys

|

|

Request a Quote

Get a fast and reliable quote for your project with just a few clicks.